Packaging: wooden box, Iron case, bared packing

Productivity: more than 100 sets one month

Transportation: Ocean,Air

Place of Origin: China

Supply Ability: more than 100 sets one monthes

Certificate: ISO9001

HS Code: 8428330000

Port: NINGBO,SHANGHAI,TIANJIN

Payment Type: T/T

Incoterm: FOB

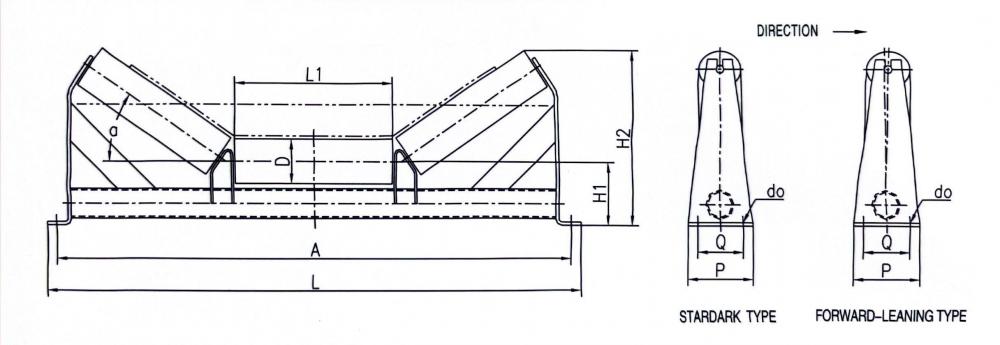

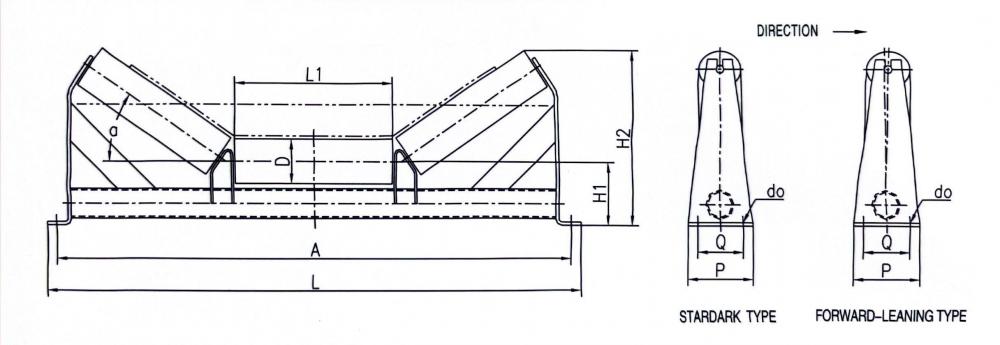

Troughing Idlers:

Revolves supporting the belt on the side which carries loads and is used for carrying bulk material ,such as sand ,earth, crushed stones ,gravel ,minerals ,grain ,etc.

There are various trough angles: 30°、35°、45°.

There are two types of idler : standard idler and forward-tilt idler. The forward-leaning idler can be arranged along all length to prevent belt sway off center condition.

Belt Conveyor Carrying Idlers features:

1. We are in desiging conveyor Rollers combines the requirements of high quality and labyrinth seal.

2. Roller Shell : consist of a selection steel tube,machined at either to strict tolerance.

3. Bearing house : Formed from strip deep pressed and calibrated to ISO M7.this tolerance allowing a perfect match between the bearing and the relevant parts on the sealing.

4. The roller shell and the two bearing housings are welded together in an way that forms a monolithic structure of exceptional strength. This method guarantees the maximum precision and the minimum out of balance forces in the rollers.

5. Seal: Triple Labyrinth Seal design is grease filled and offers an additional level of protection from contaminants impacting the bearing CEMA C, D and E Idlers have sealed for life ball bearings.

6. Wide range of working temperatures from 0º C to 100º C.

7. Final Testing: Dimension,surface, Radial circular runout,Rotational resistance,Axial load,Water immersion seal,Axial displacement,Drop test.